Training

Education

PT Diaspora Group Indonesia operates its own Training and Certification Center in Indonesia, dedicated to preparing skilled welders for both local and international markets. The center works in close collaboration with highly experienced local welding schools and companies, leveraging their wealth of knowledge and expertise to deliver comprehensive training programs. Through these partnerships, we ensure that individuals aspiring to excel in the welding industry receive top-quality education and hands-on practical skills development.

Our commitment to excellence extends beyond national boundaries. In addition to the Indonesian facility, our Testing Centre in Poland serves as a hub for advanced learning and specialized skill enhancement. Here, candidates can participate in additional training and prepare for Europen certification. This not only broadens their technical expertise but also enhances their competitiveness in the global job market.

A key advantage of training in Indonesia is the opportunity to prepare to obtain European certifications. These qualifications are recognized and respected throughout Europe, signifying a high level of proficiency and competence in welding. By earning these certifications, our graduates gain a significant career advantage, equipped to meet the highest industry standards in both European and international markets.

Welding methods

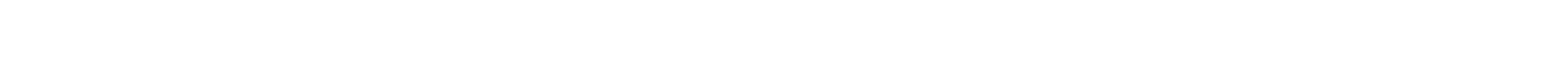

- MIG 131 (FCAW) – Gas Metal Arc Welding (solid wire).

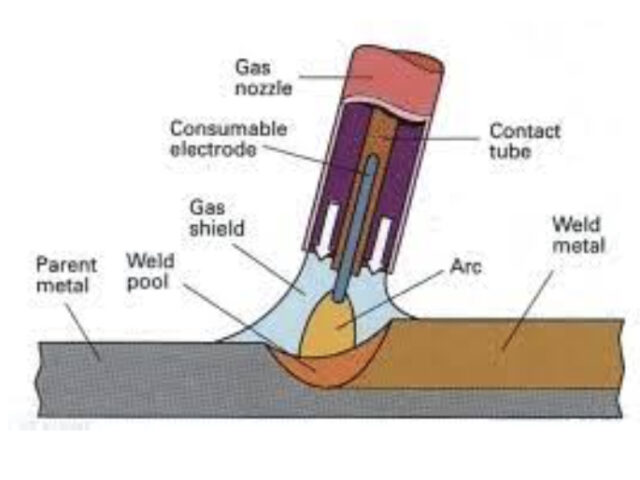

- MIG 137 (FCAW) – Flux Cored Arc Welding (flux cored).

- MAG 135 (GMAW) – Gas Metal Arc Welding (solid wire).

- MAG 136 (GMAW) – Flux Metal Arc Welding (flux cored).

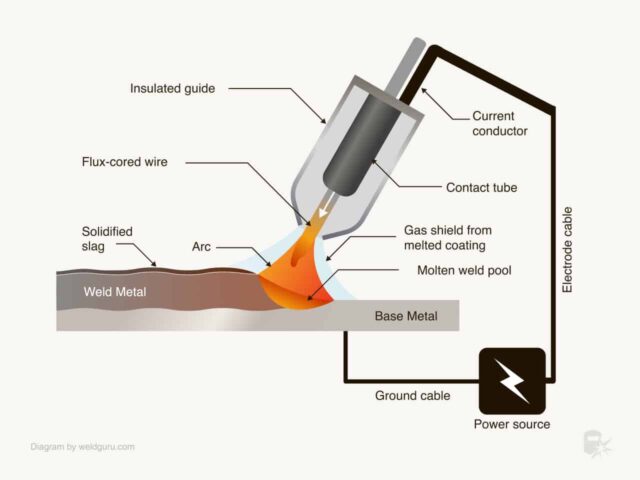

- MAG 138 (GMAW) – Metal Core Arc Welding (metal cored).

- TIG 141 (ARGON) – Gas Tungsen Arc Welding (solid wire).

Experience

At the heart of our mission lies an unwavering dedication to education and skill development that knows no geographic boundaries. By forging strong partnerships with local welding schools and offering a wealth of resources through our advanced training facility in Poland, we enable individuals to harness their full potential and thrive in the welding industry, regardless of whether they choose to pursue their career locally or embark on a global journey of excellence.

Training for European Market

MAG 135 (GMAW) – Solid Wire

Solid wire welding guarantees stronger welds because of higher deposition rates. The consistent deposition rate provided by this method ensures that the weld is structurally sound with fewer weak points, thus giving the product a longer lifespan. Furthermore, solid wire welding reduces spatter and porosity during the process compared to other methods like stick welding, which leaves behind slag that needs cleaning up when done. Solid wire welds also have an improved appearance since they produce smooth finishes without blemishes or surface imperfections. Additionally, better quality welds produced by solid wire ensure less rework, saving time and money. The versatility of solid wire welding makes it an ideal choice for different kinds of projects with varying material thicknesses. Overall, this type of welding offers a cost-effective option that requires less skill than other methods making it highly accessible even to beginners.

MAG 136 (FCAW-S) – Flux Cored

It is a flexible welding process suitable for all position welding, given the correct filler material and flux composition. Being highly productive due to the high deposition rates, it provides high quality welds with a good appearance. The high welding speed and portability of this welding method means that it is widely used in construction. This is further supported by the fact that the process can be readily performed outdoors, even in windy conditions.

Since it can be used to for a range of alloys, plain carbon, stainless and duplex steels, flux cored arc welding is also frequently used for surfacing and hardfacing.

MAG 138 (GMAW) – Metal Cored

MAG 138 is applied mainly to welding carbon, carbon-manganese and alloy steels, but may also be used for welding some stainless steel grades. Like MIG welding, success hinges on selection of the right consumables, power source, polarity on the power source, shielding gas and application technique.

FITTER. Hull and piping fitter.

Marine Pipe Fitter. Piping Technician to work on a wide range of Maritime Piping Systems and related products. Ships have a maze of pipes that carry gas, steam water and other vapours in order to run. The trade`s people that connect assemble and maintain these pipe systems are called marine Pipe Fitters. Pipe Fitters are involved in the installation and maintenance of Fire Fighting, Bilge, Hydraulic Steering, sanitary, potable water, Hot water heating, fuel, and exhaust piping system on Ships. Marine Pipe fitter fit into the group of “pipe trades,“ which deals with the installation, maintenance and repair of piping systems.

These personnel also withstand weather, from high heat to harsh cold, when they operate on drydocks. To become a shipfitter, a person needs to be able to squat, and crawl when making templates or sizing metal.